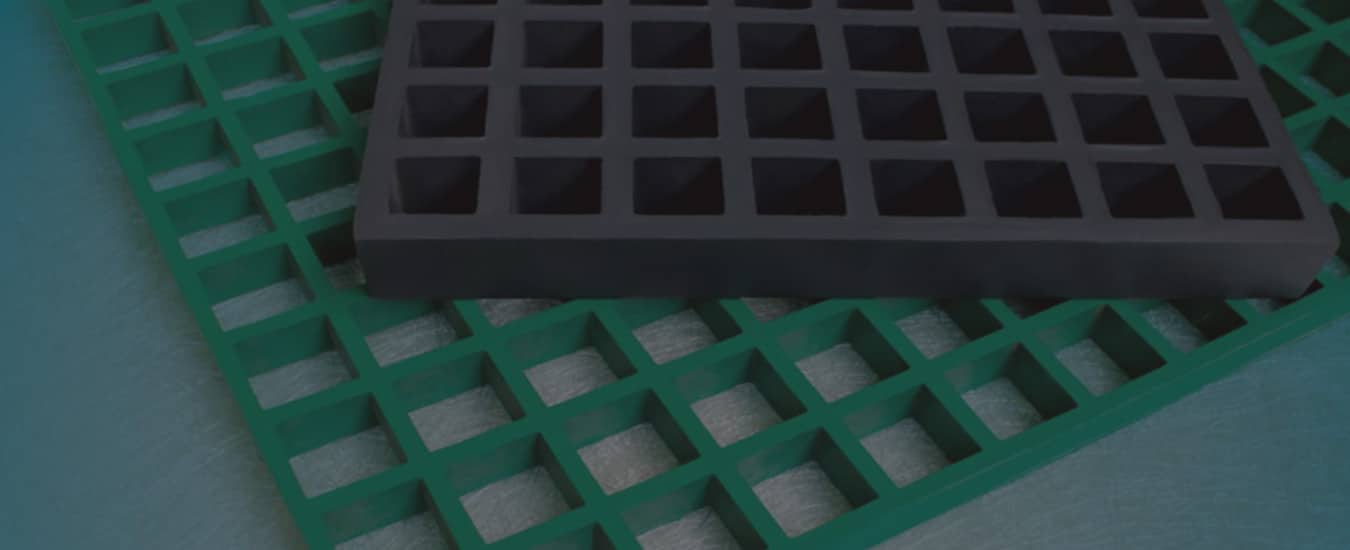

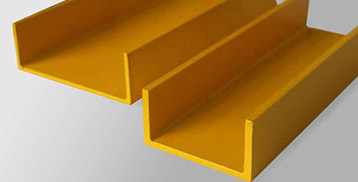

FRP resists a broad range of chemicals and is unaffected by moisture or immersion in water, making it ideal as a protective covering for surfaces where chemical spillages might occur.

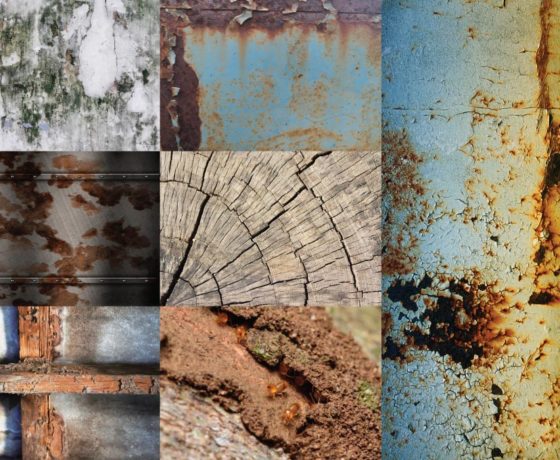

It also resists insect damage. Steel and aluminum are subject to oxidation and corrosions. They require painting or galvanizing for many applications.

Even concrete is subject to water damage. Wood can warp, rot and decay when exposed to moisture, water and chemicals. Wood is also very susceptible to attacks from insects like termites and marine borers.

When metallic materials are put into corrosive environments, they tend to have chemical reactions with the air and/or water.

The effects of corrosion become evident on the surfaces of these materials.

For example, after putting a piece of iron into a corrosive atmosphere for an extended period, it starts rusting due to oxygen interaction with water on the surface of the piece of iron.