Product Description - FRP & GRP cable tray manufacturer in india

Are you Looking FRP & GRP cable tray manufacturer in india? Electrical Cables are the arteries of the Industries and of course for the proper functioning of electrical cables are to be laid systematically and properly. The quality Cable Trays could serve this purpose very effectively and properly.

The quality Cable Trays means reliable quality and assured durability of the product. Cable Trays are designed as per the requirement of the Industry. It is of various sizes and different types. Ladder Type Cable Trays are more popular but Perforated Type Cables Trays are also having it’s own importance.

To achieve the maintenance free smooth production operation many Industries turned to FRP/GRP Industrial Products & Cable Trays. FRP/GRP Cable is also available in fire retardant quality.

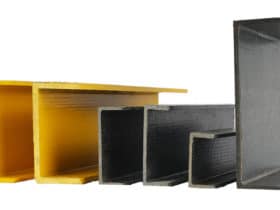

We offer an extensive range of perforated type cable trays produced using the pultrusion process. Pultrusion is a continuous, automated closed molding process that is cost effective for high volume production of cross section parts. We have an extensive selection of sizes ranging from 50mm to 1000mm width with 3mm to 5mm thickness.

Check out frp and grp grating | frp and grp pipes

Comparison chart for FRP & GRP Cable Tray

| DESCRIPTION | FIBER TECH FRP CABLE TRAYS | MILD STEEL | GALVANISED IRON |

|---|---|---|---|

| Ease in Installation | Excellent | Moderate | Moderate |

| Acid Fumes Resistance | Excellent | Low | Moderate |

| Fire Retardant | High | High | High |

| Life Span | Excellent | Good | Low |

| Electrical Conductivity | Low | High | High |

| Life Cycle Cost | Low | Moderate | Moderate |

Specifications

Side Member : ‘ C ‘ Channel Section

Middle run : 25 mm X 25mm Sq.Tube

Spilce Plate / Connector Plate : As per standard for cable tray joint

Features

1.Corrosion Resistance:

Excellent corrosion and chemical resistance. It gives resistance against almost all chemicals & in most hostile environments.

2.Fire Retardant:

Sonal Group with its special resin systems, satisfied most of the safety issues and regulations for applications. Fire retardant as per IS-6746, ASTM E 84 & others.

3.High Strength:

Sonal Group FRP Cable Trays meet NEMA Norms. (American Specification for Glass Cable Trays) ASTM, UL and EIL Standards for load bearing capabilities.

4.Low Conductivity:

Low Conductivity of heat and electricity.

5.EMI / RFI Transparent:

Transparent to electromagnetic radiations unlike GI and Aluminum Trays.

6.Maintenance Free & Life:

UV stabilized and requires no maintenance.

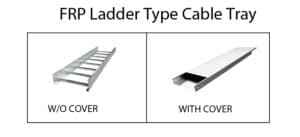

Types of Cable Trays

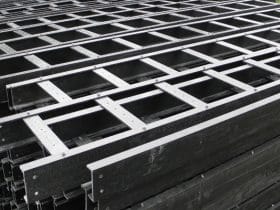

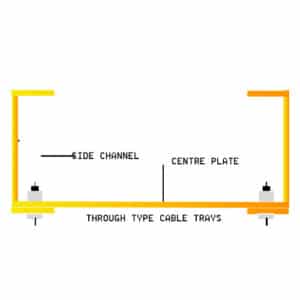

Two Longitudinal side rails connected by rungs at regular intervals. The Rungs are epoxy bonded and fastened to demonstrate high strength against Point, Side and Uniform loads.

Ladder Type Cable Trays produced by an automatic pultrusion machine we offer in an extensive range; those cable trays are made up of C shaped Side Channel.

Specification:

| Types | Specification |

|---|---|

| MOC | Polyster Resin Glass Fibres |

| Fire Retardant Property | IS-6746 Class VO |

| Standard Length | 3 Mtrs |

| Width | 150-1000mm |

| Rung Spacing | 300 mm C/C* |

| Coupler Plates | FRP plates with SSH/Ws |

| Radius of Bends | 300mm /600mm/900mm |

| Glass Content | >60% |

| Angle of Bend | 900/450/600 |

Load Table:

| Code | Side Runner (H) | Width (W) | EIL (UDL) |

|---|---|---|---|

| SG-LSCT-075 | 75/100/150 | 750 | 120kg/m |

| SG-LSCT-060 | 75/100/150 | 600 | 90Kg/m |

| SG-LSCT-045 | 75/100/150 | 450 | 75kg/m |

| SG-LSCT-030 | 75/100/150 | 300 | 60kg/m |

| SG-LSCT-015 | 75/100/150 | 100 | 30kg/m |

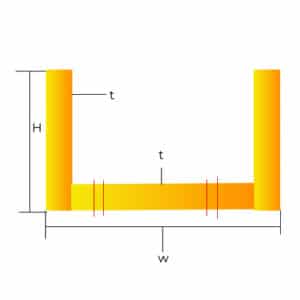

Structure with a solid or perforated bottom with integrated side rails.

Our standard FRP channel type trays include – perforated type, solid bottom, pre-drilled cable tray – which are designed for light loads namely instrumentation and control cables and for the transition from cable trays to individuals control points.

Perforated Type Size Chart: (All dimensions are in mm.)

| Width(W) | Height(H) | Thickness(T) |

|---|---|---|

| 300 | 50 | 5 |

| 250 | 50 | 5 |

| 200 | 50 | 4 |

| 150 | 50 | 5 |

| 150 | 50 | 4 |

| 100 | 50 | 6 |

| 100 | 50 | 4 |

| 100 | 40 | 4 |

| 100 | 30 | 6 |

| Width(W) | Height(H) | Thickness(T) |

|---|---|---|

| 100 | 30 | 5 |

| 100 | 30 | 4 |

| 100 | 30 | 3 |

| 75 | 50 | 4 |

| 75 | 30 | 4 |

| 75 | 25 | 3 |

| 60 | 30 | 5 |

| 60 | 30 | 3 |

| 50 | 50 | 4 |

Structure with a solid or perforated bottom with integrated or separate longitudinal side rails.

Manufactured according to customers requirements.

GRP Cover for Cable Tray :

Cover Dimension Size Chart

| Dimension-A | Dimension-B | Dimension-T |

|---|---|---|

| 300 | 15 | 3 |

| 200 | 15 | 3 |

| 150 | 15 | 3 |

| 150 | 15 | 4 |

| 150 | 15 | 3 |

| 50 | 15 | 3 |

| 50 | 15 | 4 |

Applications

- Electrical substations

- Road Divider Fencing

- Garden Fencing

- High voltage pylons

- Live plant in general

- Transformer buildings

Advantages

- Resistance to saline water, sulphur, chlorine and other basic environments

- Recommended in chlorine environments

- No earthing required

- Easy to work at the site and is much easier to move and place

- No burring, no finishing required and no risk of injury

- Excellent electrical and thermal insulation